The shrimp industry in Vietnam is among the largest globally, producing vast quantities of shrimp each year. However, a significant by-product of shrimp production, the shells, often goes to waste, causing environmental challenges due to slow degradation rates. But what if these shells could be transformed into valuable resources?This is where the extraction of chitosan, a biopolymer derived from chitin found in shrimp shells, comes in. Chitosan has diverse applications in agriculture, pharmaceuticals, food, and environmental management, making it a sustainable solution for managing shrimp shell waste while contributing to various industries.

Chitosan Extraction Process: A Triple-Step Approach

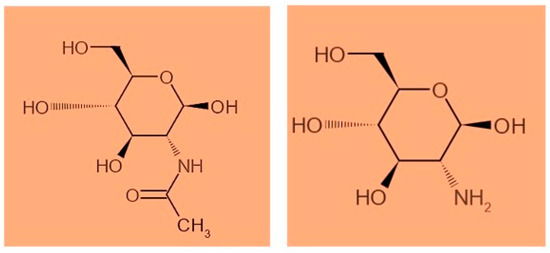

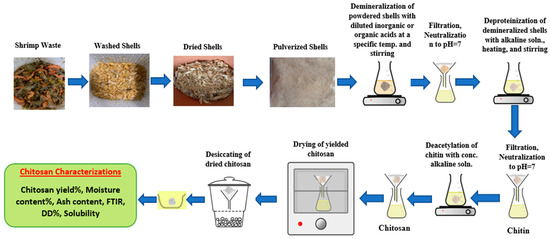

The extraction of chitosan from shrimp shells typically involves a three-step chemical process:

- Demineralization: The shrimp shells are first treated with acid to remove minerals like calcium carbonate. This step is crucial for ensuring the purity of the chitosan.

- Deproteinization: The proteins that bind with chitin in the shell are removed using an alkaline solution, usually sodium hydroxide, leaving behind the chitin structure.

- Deacetylation: In this final step, chitin is treated with a concentrated alkaline solution to remove acetyl groups, converting it into chitosan. The degree of deacetylation determines the final properties of the chitosan.

Vietnam’s Opportunity: A Competitive Advantage

Vietnam’s thriving shrimp industry offers a unique opportunity to capitalize on the vast amounts of shrimp shells generated annually. By optimizing the chitosan extraction process, these shells can be converted into a biopolymer with a wide array of applications, including in agriculture as a natural pesticide, in water treatment for waste management, and in the biomedical field for wound healing and drug delivery.

The Role of Technology in Optimizing Chitosan Extraction

Recent advancements in artificial neural networks (ANNs) have proven to be beneficial in predicting the factors that affect chitosan yield. These technologies can optimize the extraction process by considering multiple variables, such as the concentration of acids and alkalis, time, and temperature for each extraction stage. For Vietnam, leveraging these technologies could help enhance efficiency, reduce energy consumption, and lower environmental impact, turning shrimp shell waste into high-value products.

Environmental and Economic Benefits

The environmental impact of shrimp shell waste disposal can be severe, with improper disposal methods leading to pollution and ecological harm. By investing in chitosan extraction, Vietnam can create a circular economy where shrimp shell waste is not only reduced but also converted into a valuable product. This would align with global sustainability efforts and the push for environmentally friendly solutions in agriculture and industry.Economically, the production of chitosan from shrimp shells is relatively low-cost, making it a promising opportunity for Vietnam’s agricultural and industrial sectors. The global demand for biopolymers like chitosan is on the rise, especially in emerging markets that prioritize sustainability. By tapping into this growing market, Vietnam can strengthen its position as a leader in sustainable production and waste management.

Chitosan’s Versatile Applications in Vietnam’s Industries

In Vietnam, chitosan has the potential to revolutionize several sectors:

- Agriculture: Chitosan can be used as a natural biopesticide and soil conditioner, offering an eco-friendly alternative to chemical pesticides.

- Water Treatment: The ability of chitosan to bind with pollutants makes it an effective agent in wastewater treatment, which is especially beneficial for Vietnam’s growing urban centers.

- Food and Pharmaceuticals: Chitosan is widely used in food packaging, as well as in pharmaceuticals, where its antimicrobial properties can be harnessed to produce safer products.

Looking Ahead: A Sustainable Future for Vietnam’s Shrimp Industry

With the growing importance of sustainability, Vietnam’s shrimp industry has an exciting opportunity to reduce waste, protect the environment, and create new economic opportunities. By adopting advanced techniques for chitosan extraction and optimizing production processes, the country can unlock the full potential of shrimp shells, contributing to global efforts toward waste reduction and sustainable production.Vietnam is well-positioned to become a leader in the sustainable extraction of chitosan, offering a solution that benefits the environment, the economy, and industries that rely on biopolymers. Embracing this innovative approach will not only help mitigate the ecological footprint of the shrimp industry but also turn waste into wealth.